|

| Timing Belts |

Timing belts of various teeth profiles, tooth pitches, pitch lengths, widths, materials & strengths suiting different applications and needs are available in the market. Some manufacturers also provide customized special purpose belts on orders.

Structure of Timing Belts

- Rubber back body protects cords from damage and keeps oil, dirt, grease and other foreign particles away from cords.

- Timing belts carries equally spaced Cords, which are housed between rubber back body and inner profile teeth. These Cords are made of fibre glass and have high tensile strength, which takes load during machine run and protects belt from breaking under load. Polyurethane (PU) belts carries steel wire rope cords, which provides extra heavy duty strength and are used where belt failure rate is high and where the access to change belt needs more time and efforts.

- There are various types of teeth profiles available suiting different operational needs. Inner teeth are covered with nylon fabric which strengthen teeth against wear and abrasion.

Nomenclature of Timing Belts

When

replacing belt or placing an order to buy belt from market, a specific naming

i.e., nomenclature helps in identifying right size belt. Till late 90s,

conventional belts with trapezoidal teeth were in existence and thereafter

belts with circular teeth came in market and became popular in industry. For

both the belts, different naming scheme is used.

- Nomenclature

of conventional belt with Trapezoidal teeth ;

There

are two series available in Trapezoidal profile teeth belts ;

- Trapezoidal teeth timing belt – Inch Series

To define this belt, we need belt pitch length, tooth pitch and belt width. For example, if ordering a 15 inches long belt, whose tooth pitch is 0.2 inch or 1/5 inch and width is 0.75 inch or 3/4 inch then nomenclature will be "150 XL 075". Various standard tooth pitches available are given in the following table. Tooth pitches can be selected from the following table.

To define this belt, we need belt pitch length, tooth pitch and belt width. For example, if ordering a 15 inches long belt, whose tooth pitch is 0.2 inch or 1/5 inch and width is 0.75 inch or 3/4 inch then nomenclature will be "150 XL 075". Various standard tooth pitches available are given in the following table. Tooth pitches can be selected from the following table.- Trapezoidal teeth timing belt – Metric Series

To define this belt, we need belt pitch length, tooth pitch and belt width. For example, if ordering a 1500 mm long belt, whose tooth pitch is 5 mm and width is 40 mm then nomenclature will be "1500 T5 40". Various standard tooth pitches available are given in the following table along with their abbreviations. Tooth pitches can be selected from the following table.

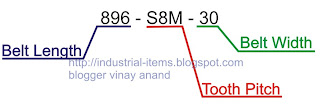

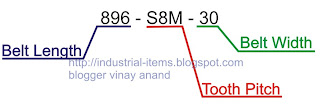

To define this belt, we need belt pitch length, tooth pitch and belt width. For example, if ordering a 896 mm long belt, whose tooth pitch is 8 mm and width is 30 mm then nomenclature will be "896-S8M-30". Belts of various tooth pitches can be selected. Available tooth pitches are 2M, 3M, 5M, 8M, 14M & 20M.

To define this belt, we need belt pitch length, tooth pitch and belt width. For example, if ordering a 896 mm long belt, whose tooth pitch is 8 mm and width is 30 mm then nomenclature will be "896-S8M-30". Belts of various tooth pitches can be selected. Available tooth pitches are 2M, 3M, 5M, 8M, 14M & 20M.

There is slight difference in teeth of belts having pitch start from T and AT like teeth height, etc.

2. Nomenclature of timing belt with curvilinear teeth ;

Following types of circular or curvilinear teeth are available ;

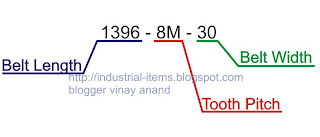

- HTD (High Torque Drive) or conventional curvilinear teeth timing belt ;

To define this belt, we need belt pitch length, tooth pitch and belt width. For example, if ordering a 1396 mm long belt, whose tooth pitch is 8 mm and width is 30 mm then nomenclature will be "1396-8M-30". Belts of various tooth pitches can be selected. Available tooth pitches are 2M, 3M, 5M, 8M, 14M & 20M.

- STD (Super Torque Drive) or modified curvilinear teeth timing belt ;

To define this belt, we need belt pitch length, tooth pitch and belt width. For example, if ordering a 896 mm long belt, whose tooth pitch is 8 mm and width is 30 mm then nomenclature will be "896-S8M-30". Belts of various tooth pitches can be selected. Available tooth pitches are 2M, 3M, 5M, 8M, 14M & 20M.

To define this belt, we need belt pitch length, tooth pitch and belt width. For example, if ordering a 896 mm long belt, whose tooth pitch is 8 mm and width is 30 mm then nomenclature will be "896-S8M-30". Belts of various tooth pitches can be selected. Available tooth pitches are 2M, 3M, 5M, 8M, 14M & 20M.

. Belts with teeth at both sides are also available. These belts come in use, when drive from motor or gear box has to give to more than one timing pulley rotating in opposite directions. Again available tooth pitches are 2M, 3M, 5M, 8M, 14M & 20M.

Sometimes when numbers marked on belts are erased due to friction, it becomes difficult to identify belt because it is neither easy nor reliable to measure belt's length as it elongates extensively during time of use and also from the portion it breaks. In such case, we can measure tooth pitch and count the number of teeth. The multiplication of both will give us belt length. Width can be measured easily.

Open ended belts are also provided by manufacturers which are cut as per size required in zig-zag format called fingers, from both the ends and jointed with the help of punching machine or press machine under application of heat, which is called finger joint. Apart from open ended belts, different manufacturers make special purpose belts as per need and demand of industry.

Open ended belts are also provided by manufacturers which are cut as per size required in zig-zag format called fingers, from both the ends and jointed with the help of punching machine or press machine under application of heat, which is called finger joint. Apart from open ended belts, different manufacturers make special purpose belts as per need and demand of industry.

Advantages of timing belts ;

- Timing belts are highly precise & efficient because these belts do not slip like flat belts or V-belts.

- As there is no metal to metal contact like gears, timing belts are quieter and wear less during operation over the period of time. Also no lubrication is required.

- Strong, light weight & cheaper.

- Can be used for high speed applications.

- Timing Belts can be used for comparatively longer centre distances between shafts than chain drives.

Care for Timing Belts ;

- In operation (while doing preventive maintenance of the machine, technicians should take care of following points related to timing belts to avoid frequent breaking) ;

- Environment surrounding belts should be clean free from oil, grease, moisture, dirt and other foreign particles.

- Belts wearing from one side that may be because of mis-alignment of pulleys. Pulleys must be re-aligned in such cases.

- When the pulley is too small and the centre distance is also too small then idler must use at the slack side to increase teeth engagement on the smaller pulley and to avoid breaking.

- When belts break too frequently then its tension must be re-adjusted.

- Remove belts and never let belts run idler, if some operation has to stop in machine for a long period of time as it also leads to wear and tear.

- Store in cleaner place free from oil, grease, moisture, dirt and other foreign particles.

- Do not keep belts in twisted position while storing belts.

- Do not put excessive loads on belts as its teeth may deform, which may affect normal working.

Few other posts seeking your attention ;

More at ; Scientific Laws

>> Shiv Chalisa

More at ; Bhakti Sangrah

Liked the post. Looking forward for more like this.

ReplyDeleteSmall Timing Pulley manufacturers

Dear Praveen G

DeleteThanks for interest. Definitely, I am continuously working to bring more interesting contents.

Really well put! I hope he reads it.One size belts

ReplyDeleteHi Ander Lee,

DeleteThanks for visiting my page.

The use of a pulleys and belt in automobiles are very important. They are essential components of your car's internal combustion engine application that is responsible for controlling the opening and closing of the engine valves.

ReplyDeleteDear Rhen Nicey,

DeleteThis is very true that belts and pulleys are used to transmit power and motion. Timing belts & their pulleys are responsible for controlling time of opening and closing of engine valves.

Today timing belts are not only used for auto-mobiles but also they have vast uses in other industrial applications. Manufacturers not only make general purpose timing belts but they also make belts for special purposes like some special coating at back surface or some kind of groove, etc.